CORE TECHNOLOGY

About OGASAKA

4TECHNOLOGY

F.F.S:Front Float System

![]()

The combination of Front Rocker profile, in which snow contact point at the ski tip is moved closer to the center and Front Lead Function (F.L.F) interacts to disperse the snow resistance optimally at the ski tip while turning and provides stable edge grip and acceleration regardless of snow conditions and situation.

F.L.F:Front Lead Function

![]()

F.L.F provides easy ski deflection while edging and allows a skier to move the mass inside the turn, which enables effortless and quick turning into the fall line.

The more edge angle increases, the longer effective edge length engaged on snow enhances, which produces more edge grip and stability.

Also, enhanced effective edge length provides easy speed control. (PAT. No. 3837716)

STB:Stabilizer

![]()

STB delivers a skier’s power directly to a ski from the tip to the tail, reducing the vibration from the snow surface. It allows a stable smooth skiing.

PPF:Powerplatformfunction

![]()

PPF makes a greater ski functionality in terms of rigidity by placing a sheet made by aluminum alloy in the core. It allows higher grip, and flexibility on the top and the tail of a ski. It also permits stable skiing by preventing deflection of a ski. PPF could be placed over or under the core.

3CONSTRUCTION

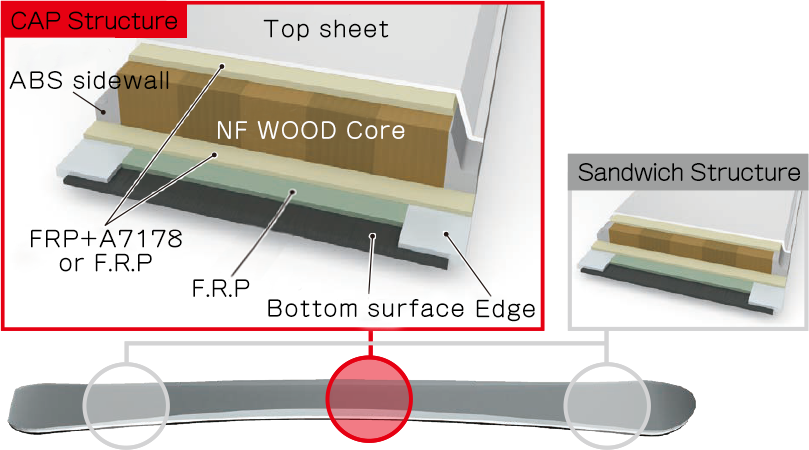

Sandwich Structure

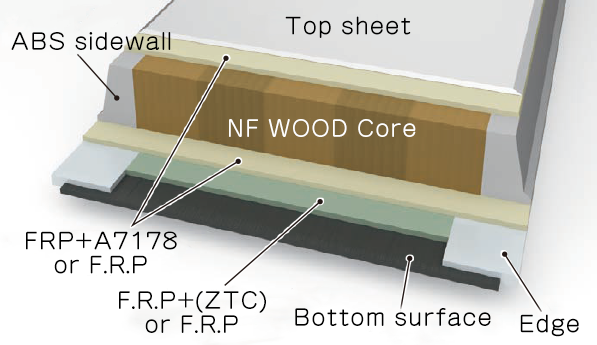

This is the most basic type of ski structure. Both above and below the wood core are laminated by sheets such as special F.R.P. and A7178 to build strengths.Since each component is laminated in this structure it minimizes the risk of an internal deformation when skis are warped. This enables you to transmit the pressure on skis directly onto the surface of snow.Also, skis with this structure will hold the pressure on it while you make a turn, which makes your skiing style more orthodox and moderate.

Twin Keel Structure

This structure is our original structure using both sandwich and cap structure. The center is made with cap structure, allowing higher torsion, and the shoulder and the tail are made with cap structure, allowing high flexibility. Also, “ABS side wall,” which absorbs impacts is used along the side of a ski. This structure is the mixture of three technologies that makes higher torsion, flexibility, and damping. (PAT. No. 2608528)

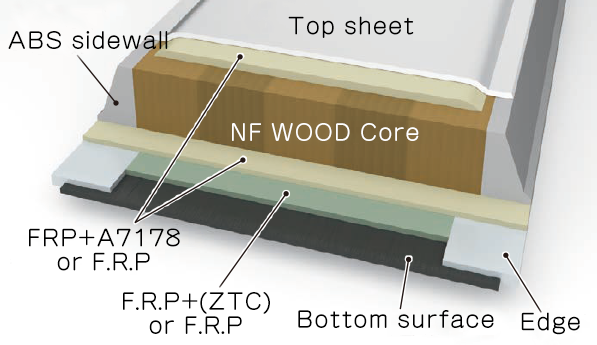

Shell Top Structure

This structure is the same structure as the sandwich structure except that both sides of a top sheet are slightly lowered. This is more sophisticated structure compared to sandwich structure in sense that it is more resistant to external shocks.